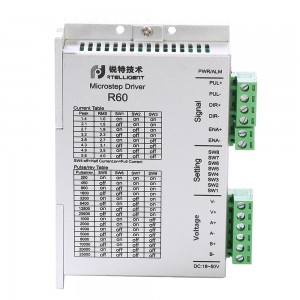

Advanced Pulse Control Digital Stepper Drive R86

Kenyelletso ea Sehlahisoa

Khokahano

Likaroloana

| Phepelo ea motlakase | 20 - 80 VAC / 24 - 100VDC |

| Output Current | Ho fihla ho 7.2 amps (boleng ba tlhoro) |

| Taolo ea hajoale | PID algorithm ea taolo ea hajoale |

| Litlhophiso tsa Micro-steping | Litlhophiso tsa phetoho ea DIP, likhetho tse 16 |

| Lebelo la lebelo | Sebelisa enjene e loketseng, ho fihla ho 3000rpm |

| Khatello ea resonance | Ka tsela e iketsang bala sebaka sa resonance ebe o thibela ho sisinyeha ha IF |

| Phetoho ea parameter | Bona paramethara ea enjene ka bo eona ha Mokhanni a qala, ntlafatsa ts'ebetso ea taolo |

| Pulse mode | Tataiso & pulse, CW/CCW ho otla habeli |

| Ho hloekisa pelo | Sefahla sa 2MHz sa dijithale se sebetsang |

| Boemo bo sa nke lehlakore | Halofo ea hona joale ka halofo ka mor'a hore koloi e eme |

Boemo ba Hona Joale

| Peak Current | Karolelano ea Hona Joale | SW1 | SW2 | SW3 | Litlhaloso |

| 2.4A | 2.0A | on | on | on | Tse ling tsa Hona joale li ka etsoa ka mokhoa o ikhethileng |

| 3.1A | 2.6A | tima | on | on | |

| 3.8A | 3.1A | on | tima | on | |

| 4.5A | 3.7A | tima | tima | on | |

| 5.2A | 4.3A | on | on | tima | |

| 5.8A | 4.9A | tima | on | tima | |

| 6.5A | 5.4A | on | tima | tima | |

| 7.2A | 6.0A | tima | tima | tima |

Micro-steping Setting

| Mehato/phetohelo | SW5 | SW6 | SW7 | SW8 | Litlhaloso |

| Ea kamehla | on | on | on | on | Likarolo tse ling li ka etsoa ka mokhoa o ikhethileng. |

| 800 | tima | on | on | on | |

| 1600 | on | tima | on | on | |

| 3200 | tima | tima | on | on | |

| 6400 | on | on | tima | on | |

| 12800 | tima | on | tima | on | |

| 25600 | on | tima | tima | on | |

| 51200 | tima | tima | tima | on | |

| 1000 | on | on | on | tima | |

| 2000 | tima | on | on | tima | |

| 4000 | on | tima | on | tima | |

| 5000 | tima | tima | on | tima | |

| 8000 | on | on | tima | tima | |

| 10000 | tima | on | tima | tima | |

| 20000 | on | tima | tima | tima | |

| 40000 | tima | tima | tima | tima |

Tlhaloso ea Sehlahisoa

Ho hlahisa Mokhanni oa Digital Stepper - Ho notlolla ho nepahala le ho sebetsa hantle

Mokhanni oa stepper oa dijithale ke sesebelisoa se tsoetseng pele, se sebetsang ka bongata se fetolang tsela eo li-motor tsa stepper li laoloang ka teng. E entsoe ka theknoloji e tsoetseng pele, koloi e na le likarolo tse ngata tse ikhethang tse netefatsang ts'ebetso e ntle, e nepahetseng le e sebetsang hantle. Haeba u batla mokhanni ea ka tšeptjoang le ea sebetsang hantle oa stepper, u se ke ua sheba hole le bakhanni ba stepper ba dijithale.

E 'ngoe ea likarolo tsa bohlokoa tsa li-drive tsa stepper tsa dijithale ke ho nepahala ha tsona ho ke keng ha bapisoa. Mokhanni o sebelisa li-algorithms tse tsoetseng pele tsa ts'ebetso ea mats'oao ho netefatsa taolo e nepahetseng ea li-motors tsa stepper bakeng sa motsamao o se nang seam, o boreleli. Ka bokhoni ba eona ba ho rarolla li-microstep, koloi e finyella ho nepahala ha boemo bo botle esita le lits'ebetsong tse hlokang ka ho fetisisa.

Ho feta moo, mokhanni oa stepper oa dijithale o fana ka taolo e feto-fetohang ea hajoale, e lumellang basebelisi ho ntlafatsa ts'ebetso ea makoloi ha ba ntse ba thibela ho chesa haholo. Tšobotsi ena ha e tiise feela bophelo bo bolelele ba motor stepper, empa hape e fokotsa tšebeliso ea matla, e etsa hore e be khetho e ntle ea tikoloho bakeng sa likhoebo le batho ka bomong.

Tlhahisoleseding ya Sehlahiswa

Ntle le ho nepahala le ho sebetsa hantle, li-drive tsa dijithale tsa stepper li fana ka mefuta e mengata. Mokhanni o na le likhetho tse fapaneng tsa ho kenya tse kang pulse/direction kapa matšoao a CW/CCW, a etsa hore e lumellane le mefuta e fapaneng ea litsamaiso tsa taolo. Ho feto-fetoha hona ho etsa hore e loketse liindasteri tse fapaneng, ho kenyeletsoa liroboto, li-automation, khatiso ea 3D, lisebelisoa tsa mochini oa CNC, le tse ling.

Ho feta moo, bakhanni ba stepper ba dijithale ba bonolo haholo ho sebelisa. E na le sebopeho se hlakileng le phanele ea taolo e bonolo ho basebelisi, e ka hlophisoa habonolo le ho etsoa ho latela litlhoko tse ikhethileng. Boholo ba eona bo kopaneng le ts'ebetso e bonolo ea ho kenya e etsa hore e be khetho e bonolo bakeng sa ts'ebeliso efe kapa efe ea enjene ea stepper.

Polokeho e boetse e le eona ntho e tlang pele molemong oa moralo oa mokhanni oa dijithale. E na le ts'ireletso ea potoloho e khuts'oane, ts'ireletso ea ho feta-voltage, ts'ireletso ea mocheso o feteletseng le mesebetsi e meng ho netefatsa ts'ebetso e tšepahalang le e bolokehileng ea motor ea stepper tlasa maemo a fapaneng. Mokhanni enoa o u fa khotso ea kelello ea ho tseba hore sesebelisoa sa hau se sirelelitsoe tšenyo e ka bang teng.

Ka kakaretso, bakhanni ba li-stepper tsa dijithale ba fetola papali ea taolo ea motor stepper. Likarolo tsa eona tse hlahelletseng, tse kenyelletsang ho nepahala, ho sebetsa hantle, ho feto-fetoha ha maemo, ho sebelisana hantle le basebelisi le polokeho, li etsa hore e be e loketseng bakeng sa lits'ebetso tse fapaneng. Ntlafatsa sistimi ea hau ea ho laola motor ea stepper kajeno 'me u bone ts'ebetso e ntlafalitsoeng le ts'epahalo ea bakhanni ba dijithale tsa stepper.

-

Buka ea mosebelisi ea Rtelligent R86-IR

Buka ea mosebelisi ea Rtelligent R86-IR -

Fetola Buka ea Mosebelisi ea Rtelligent R86-IO

Fetola Buka ea Mosebelisi ea Rtelligent R86-IO